ECHOO is your aftermarket specialist for crawler crane parts. We offer new parts, aftermarket parts, re-machined parts for your machine's undercarriage.Keep up with undercarriage parts and undercarriage repairs and save money with aftermarket replacement parts for your Link-Belt or American crane etc with ECHOO.

Link-Belt or Hitachi etc undercarriage parts are in Stock at ECHOO!!!

Maintaining Your Crawler Undercarriage

Maintaining your tracked undercarriage is important to keep your crawler crane running in top condition. Here are a few tips for maintaining your tracks :-

- Inspect the tracks and components regularly and listen to them work – high pitched noises/squealing indicate wear points.

- Check the tension of the tracks chains as per the manufacturer’s guide. Loose tracks mean exacerbated wear. crawler undercarriage. Adjust as needed.

- Clean the undercarriage to remove dirt, debris, and other contaminants especially around the sprocket and idler areas. Packing of debris will act like an angle grinder!

- Check track shoe,final drive,roller and sprocket bolts and nuts as per the service requirements laid out in the machine operating manual. A loose bolt will cause elongation and expensive damage.

- Feel for heat spots in track rollers and idler centres – these indicate loss of lubricant and imminent failure.

Sourcing Crawler Undercarriage Parts

ECHOO is here to supply you with all your crawler crane undercarriage parts. We stand out from our competitors. Our prices are realistic, and our component quality is not negotiable.

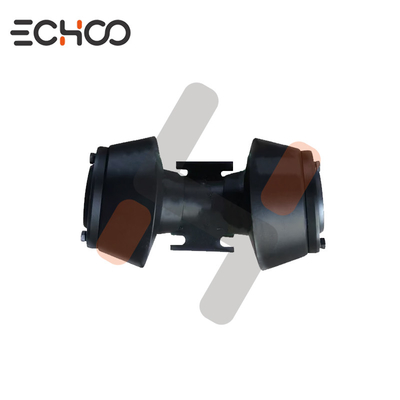

The shells of our track rollers are manufactured from heard-wearing 40Mn2 steel, extending service life. The bushings are industry-leading 6-10 mm thick pure copper rather than a less hard-wearing duplex combination of iron and copper, and our pins are made of tested and tried robust 42cr steel.

This attention to quality and performance is the same across the range – track shoe assemblies, chains with conventional bolt-on pads, idlers, and sprockets, all built to fit, work, and last.

Supported manufacturers

We cover small, medium, large and very large cranes (up to 800 T) manufactured by leading industry names – American, Fuwa, Hitachi, Hitachi Sumitomo, IHI, Kinki Ishiki, Kobelco, Lima, Liebherr, Link-Belt, Manitowoc, Nippon Sharyo, Ruston Bucyrus, , Sany, Sumitomo, Terex Demag, XCMG, Zoomlion along with others.

For more information on how Astrak can help you maintain your crawler crane undercarriage, please contact our team on 86-592-503-1397.

※※※Keep in mind that part numbers change, check with one of our professionals to verify part numbers and locate the correct part for your machine, part numbers used are for reference only and do not imply that these are parts produced by the original equipment manufacturer.※※※