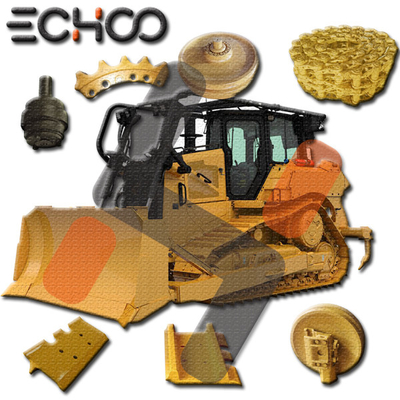

The undercarriage of a compact track loader (CTL) is critical to its performance across construction, agriculture, and mining. Key components—track rollers, top rollers, idlers, drive sprockets, and rubber tracks—work synergistically to ensure efficiency, durability, and safety.

Core Components & Functions

Track rollers guide track movement, distribute machine weight, and minimize ground pressure.

Top rollers support the track’s upper section, reduce sagging, and lower friction to extend track lifespan.

Front idlers adjust track tension and steering, preventing slippage or over-tightening.

Drive sprockets convert engine torque into track motion, controlling speed and direction.

Rubber tracks enhance ground stability on soft terrain, improve traction, and absorb shocks for smooth operation.

Significance of Undercarriage Quality

Stability & Adaptability: High-quality components ensure reliable performance on uneven or muddy surfaces, reducing vibrations and operational risks.

Durability: Wear-resistant rollers and tracks minimize maintenance needs, extending the machine’s service life.

Load Capacity: Robust idlers and rollers enable safe heavy-load operations in demanding environments like mining.

Cost Efficiency: Durable parts reduce downtime and long-term expenses despite higher initial costs.

Safety: Regular inspection of sprockets and tracks prevents failures that could lead to accidents.

If you want to learn more details, please don't hesitate to contact us.

Wechat/Whatsapp: +86 177 5075 6029

email: service@echoo.cn

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!