Ingenious Forging: The Quality Journey of Excavator Track Rollers

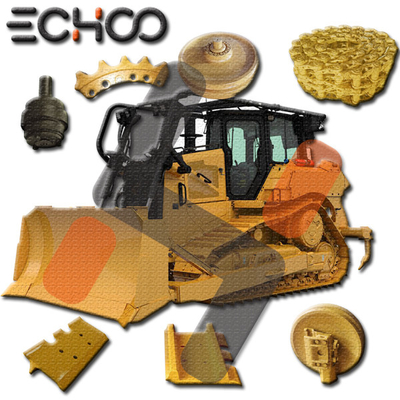

The excavator track roller is the "load-bearing core" of tracked equipment, and its quality is directly related to construction efficiency and equipment service life. We have achieved wear-resistant and durable reliable components through strict control throughout the entire process.

We strictly control the material quality from the source, only selecting 40Mn2 high-strength alloy steel. Each batch of materials is inspected for composition with a spectrometer to ensure that harmful elements such as sulfur and phosphorus are half lower than the industry standard, fundamentally ensuring the wheel body is both tough and strong. In the forging process, a 6300-ton hot die forging press is used to press the 1150℃ steel billet into shape in one go. The resulting wheel body has fine grains and high density, with a tensile strength more than 30% stronger than ordinary processes. Machining relies entirely on CNC lathes and machining centers. For key parts such as inner holes and wheel flanges, the tolerance can be controlled to ±0.015 mm. After processing, each one is inspected with a coordinate measuring machine, and those with inaccurate dimensions are directly rejected.

Heat treatment is the key to wear resistance. We adopt "overall quenching and tempering + surface quenching": first, overall quenching and tempering are carried out to give the wheel body an overall toughness of 28-32HRC, making it resistant to impact; then, medium-frequency quenching is performed on the wear surface of the wheel flange, the hardened layer can reach 3-5 mm, and the surface hardness reaches 55-60HRC, which can withstand years of wear on the construction site. The sealing is also not perfunctory. Imported double-lip oil seals and dust covers are installed, and high-temperature grease must be applied. After installation, 0.3MPa air pressure is applied for 10 minutes for testing, and any leakage is not allowed. This is to prevent sand and water from entering and damaging the bearings. Finally, the finished products must pass "three inspections": fluorescent flaw detection to check for cracks, 1.5 times the rated load pressed for 10 minutes to check for deformation, and simulating construction site working conditions to run for 200 hours to measure wear. Only those that are fully qualified are allowed to be stored in the warehouse.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!