Why are chassis components the "invisible cornerstone" of machinery safety?

As the "load-bearing skeleton" of heavy equipment, core chassis components, heavy equipment is vulnerable to steering deviation, component fractures, or even loss of control if fitted with inferior parts. Choosing high-quality components is thus a fundamental safety guarantee.

Three key criteria for premium chassis parts:

Material & craftsmanship: Opt for high-strength alloy steel/wear-resistant forged aluminum, paired with electrophoresis + galvanizing anti-rust processes. Smooth welds and precise threads ensure resistance to heavy-load impacts and corrosion.

Compatibility: "Equipment-specific" parts must match the model, load parameters, and mounting holes—forced installation of mismatched components causes uneven stress and chassis damage.

Brand reputation: Select brands with heavy equipment R&D qualifications and comprehensive warranties; avoid "three-no" products (no manufacturer info, production date, or certification), which fail under heavy loads.

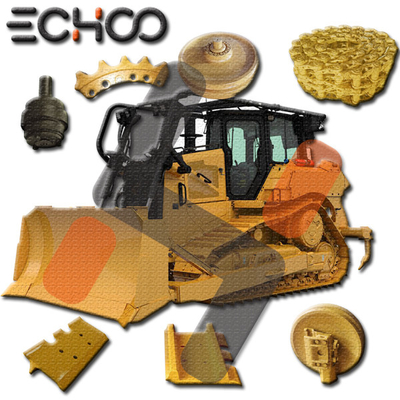

ECHOO meets these rigorous demands:

Top-tier materials: Heavy-duty high-strength alloys + aerospace-grade wear-resistant aluminum, tested through 100,000 heavy-load vibration, salt spray, and high-low temperature cycles—30% longer service life than ordinary parts.

Precise fit: Compatible with global mainstream heavy equipment (engineering/commercial/special vehicles), adhering to OE standards with no extra installation adjustments.

Reliable brand: 20 years of industry experience, ISO9001/TS16949 certifications, 1-3 year warranty, and nationwide service support.

Great value: 20%-40% more cost-effective than comparable imports via large-scale production and optimized supply chains.

Chassis components are heavy equipment’s "invisible safety barrier." ECHOO delivers heavy-duty quality, precise compatibility, and peace of mind—helping enterprises secure reliable safety without overspending. Choosing ECHOO means choosing responsibility for your equipment and team.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!