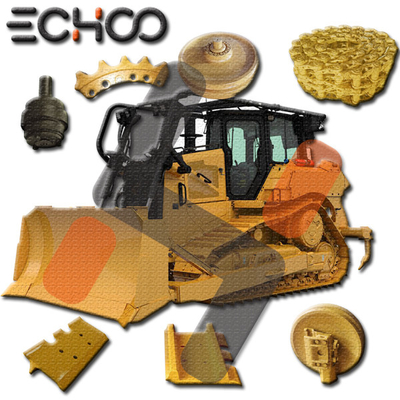

Sprocket for Ditch Witch 175-736 Drilling Machine Undercarriage Components

Product Features

-

Power Transmission: Transfers engine power to the track chain, enabling stable operation on uneven surfaces (e.g., mud, gravel).

Durability: Manufactured from high-strength alloy steel or hardened carbon steel, often with surface treatments (e.g., carburizing, coatings) for enhanced wear resistance.

Precision Fit: Tooth profile and pitch are engineered to match Ditch Witch OEM track chains, minimizing slippage or misalignment risks.

Purchasing Considerations

-

OEM Certification: Purchase from authorized Ditch Witch dealers for quality assurance and warranty coverage.

Aftermarket Alternatives: Verify critical specs (tooth count, pitch, bore diameter) if opting for third-party sprockets.

Material & Manufacturing

Material: High-carbon steel/alloy steel for impact resistance and extended service life.

Production Process: Precision forging + heat treatment (quenching, tempering) for optimal hardness and toughness. Additional anti-corrosion coatings (e.g., zinc plating) may be applied for harsh environments.

FAQ

1, Can I replace the sprocket alone?

Yes, but inspect the chain’s condition. Severely worn chains should be replaced together to ensure proper engagement.

2, What type of undercarriage parts do you offer?

Steel track group, rubber track, sprocket, roller, bolts&nuts, rubber buffer, track adjuster assy, conveyor chain, conveyor belt.

3, What machines can the parts be used for?

excavators, CTL, pavers, dozers, cranes, and cold milling machines.

4,What information should I provide if I want to buy a part?

Machinery Model, Part number, or size dimension. Or you can take a picture of your machine or old parts.

5, How to extend sprocket lifespan?

Avoid overloading, clean the undercarriage frequently, and maintain adequate lubrication.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!