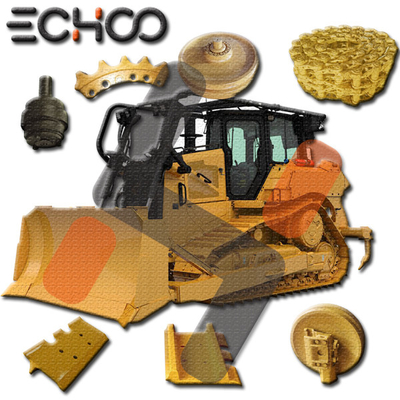

Bottom Roller Track Roller for 17ZTS Undercarriage System Supplier

Advantage

Our bottom rollers stand out with superior design and manufacturing techniques, offering significant advantages in multiple aspects. Firstly, they are made from high-strength alloy materials and undergo advanced heat treatment processes, ensuring exceptional load-bearing capacity and impact resistance, enabling stable operation even under heavy loads and harsh conditions. Secondly, the surface of the bottom rollers is specially hardened, significantly enhancing wear resistance and corrosion resistance, extending service life, and reducing maintenance costs. Additionally, the optimized sealing structure effectively prevents dust, mud, and other contaminants from entering, ensuring long-term efficient operation of internal bearings and lubrication systems. Our bottom rollers also feature shock-absorbing designs, effectively absorbing ground impacts, reducing equipment vibration, and improving operational comfort and safety. Furthermore, the diverse specifications and flexible installation methods make them compatible with various construction machinery and agricultural equipment, meeting customers' diverse needs.

Feedback

In a large-scale mining project, the client faced the challenge of frequent damage to bottom rollers under harsh working conditions, leading to increased equipment downtime and high maintenance costs. After switching to our bottom rollers, the situation improved significantly. Our bottom rollers, made from high-strength alloy materials and featuring special hardening treatments, demonstrated exceptional durability under heavy loads and complex terrains, extending their service life by over 40% compared to conventional rollers. Additionally, the optimized sealing structure effectively prevented dust and mud from entering, reducing the risk of bearing damage. Customer feedback indicated a significant improvement in equipment stability, with downtime reduced by 30% and annual maintenance costs lowered by 25%. The client highly praised our bottom rollers and expressed plans to adopt them in more equipment. This case fully demonstrates the reliability and cost-effectiveness of our carrier rollers in extreme working conditions, creating significant value for the client.

Description

| Track Roller Specifications |

| Equipment Make |

John Deere |

| Equipment Model |

17ZTS |

| Parts |

Undercarriage |

| Usage |

bottom roller |

| Always Verify Your Make And Model Before You Purchase |

FAQ

1, Are you a trade company or a factory?

Echoo is a manufacturer specializing in undercarriage parts.

2, What type of undercarriage parts do you offer?

Steel track group, rubber track, sprocket, roller, bolts&nuts, rubber buffer, track adjuster assy, conveyor chain, conveyor belt.

3, What machines can the parts be used for?

excavators, CTL, pavers, dozers, cranes,drills and cold milling machines.

4,What information should I provide if I want to buy a part?

Machinery Model, Part number, or size dimension. Or you can take a picture of your machine or old parts.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!